|

21ST Century Science & Technology New Fiber

|

|

|

|

Lian Fa DELIGHT hygroscopic perspiration yarn

|

| Characters of 100%POLY hygroscopic perspiration yarn: |

| |

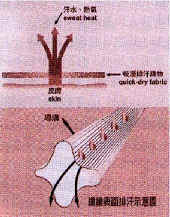

hygroscopic perspiration yarn It makes mainly use of the narrow flute in fiber surface to absorb the moisture and sweat from the skin rapidly into the surface of textile fabric by wicking, diffusion, transferring, and make evaporation, to functionalize for dryness and coolness. It also is modeled on the natural fiber in natural zoology, and is provided the fiber surface with infinite respirable pores. Besides keep its dryness, it is also soft and light in feeling and quality.

|

|

|

|

| Usages of 100%POLY hygroscopic perspiration yarn: |

| |

1. Sport suit, golf suit

2. Female underwear, bra

3. Shirt jacket, hat, socks

4. Gloves, kneecap, waist shield

5. Used for knitting and plain weaving

|

|

|

Its raw material POY is provided by South-Asia Fiber as a sole-supplier

|

|

NM Fiber:

|

| |

Main production technology are applied for electronic silk spinning, powdery fiber, film application,special treatment and processing on the post-segment. Etc. Main applied products are concentrated on the production for the mechanical textile material, filtrated material, etc, and will include the textile material for medical use in the future. Polyester fiber: The raw material of polyester processing silk is composed of polyester grey yarn and semi-stretching yarn through processing by false twisting. As the compounding fiber is provided with the natural fiber characters, imitation wool, imitation cotton and imitation silk, it can be produced to be the processing silk which provided with the bulkiness, retractility and comfortable hand-feeling. Its silk textile material is provided with washable,quick-drying,, non-ironing characters, therefore, it is the main raw material in the upstream of the textile industry.

|

|

Polyester Fiber:

|

| |

he raw material of polyester processing silk is composed of polyester grey yarn and semi-stretching yarn through processing by false twisting. As the compounding fiber is provided with the natural fiber characters, imitation wool, imitation cotton and imitation silk, it can be produced to be the processing silk which provided with the bulkiness, retractility and comfortable hand-feeling. Its silk textile material is provided with washable ,quick-drying,, non-ironing, bright glaze characters. Therefore, it is the main raw material in the upstream of the textile industry.

|

|

Rainbow Fiber:

|

| |

It is composed of the squama of Morpho butterfly¡¦s wings (radiate cobalt transparent blue and metallic glaze).In the squama of the wings, there is a pinstripe-slaty substance which provided with its regular parallel arrangement at about 0.7£gm interval, slaty substance is about 2£gm high, two sides are provided with micro-bulge like ferns. When it is irradiated, main incident light enters into the gap and makes continuous reflection, refraction and interference in the internal bulge part, to enhances the effect and form the effect with deep color. As Morpho butterfly can amplify the blue wavelength, therefore, it can appear with beautiful navy blue. If it can amplify the wavelength for other colors, the color depth and brightness can be got an amplification comparatively.

|

|

Self-Healing Fiber:

|

| |

When put apart, or scratched or abraded by extraneous force, the fiber has the function to perform self-healing. Its theory is: every part of the fiber is distributed in the multi-microcapsule which is provided with much catalyst and the polymer monomer. When it damaged, the microcapsule is also damaged, but the monomer finishes the poly-reaction rapidly and makes the fiber produce its self-healing.

|

|

Mid-Hollow Micro-Porous Fiber:

|

| |

Uses a special silk spinning procedures, and provides the inner and outer tube wall with slim grooves, and forms the porous distribution similar to the neural network. The main theory is : it applies the physic rainbow to enhance the hygroscopicity of compounding fiber, and produces the hygroscope and flash-dry. The sweats can penetrate into the grooves in the inner fiber and evaporates quickly through the grooves and porous-hole. The kind of textile material with mechanical healthy fiber can absorb the sweats rapidly and make them steamed. It is mainly applied for the sport suit and leisurewear, and it also can keep dry and comfortable.

|

|

Equilateral Quadrangle Fiber:

|

| |

The common fiber is round, the traditional high-density textile material must be used superfine fiber to decrease the fiber internal gap and increase the density of textile material. The equilateral quadrangle fiber can pile tightly depending on its geometry. So it also can produce finer quality at the same density without finer fiber, and produce the high-tech quality with paper-like cloth material and bright luster. As the tightly-piled fiber and mini-gap, after producing the high density fiber, big water drop (for rain drop) can¡¦t penetrate into it, mini-vapor( for sweat) can also be evaporated, is provided with windproof function, meanwhile with comfortable and ventilating function. It is the talent mechanical fiber, and is suitable for the fashionable coats, weatherproof clothing or sport jacket.

|

| Sweat-Volatilization Fiber: |

| |

The fiber surface is coated with the electronic ion, and also attached to some chemical substance, so it is not only high in the hygroscopicity, but also quick in the volatilization. Comparing with any fiber, natural fiber, compounding fiber, etc, it functionalizes well for the sweat-volatilization. The new products are widely used for the high-grade undergarment, welfare labor protection appliance, is provided with fine processing and its function of sweat-volatilization won¡¦t be affected if it is washed repeatedly.

|

| Self-Luminous Color Fiber: |

| |

Self-luminous color fiber is added with a small amount of luster-storage additive during producing the compounding fiber(minimum average grain is about 2¡ã3 micrometer). Irradiated by the natural light or the fluorescent lamp tube for 20-30 minutes, the product can keep its irradiance for 8-10 hours with light yellow, green, yellow, etc, during the irradiance, it can produce a permanent irradiation and light absorption. The main components of luster-storage additive are alumina and some rare earth elements. The self- luminous color terylene which developed by Dalian Compounding Fiber Research Institute, can meet the demand for producing self-luminous color cloth into special police uniform, environmental sanitation uniform, mine uniform ,etc. It can reduce the damaged and injured persons and possessions loss. As the self-luminous color fiber can perform self-irradiance without any extraneous energy, and is provided with convenient use. It is safe ,waterproof and also can be used for decoration, alarm, etc.

|

|

Antibiotic Healthy NM Fiber:

|

| |

In the antibiotic fiber, the high molecule resin is added with antibiotic additive, and get the antibiotic compounding fiber through spinning. The distribution homogeneity of NM antibiotic additive plays a key role in the high polymer spinning technology and product performance. It depends not only on affinity between the surface tension of inorganic powdery and the high polymer, but also on treatment technology on the surface of the inorganic powdery and blending technology, etc. NM antibiotic fiber not only can be produced into finished products with itself, but also can be produced into finished products blended with cotton, line, wool, silk, artificial fiber and other compounding fiber blending, it can also be used for producing the waterproof cloth, filtered-cover of air-conditioner, undergarment, operation uniform, sport suit, bedcover, medical textile commodities, etc.

|

|

Anti-ultraviolet Polyester Tri-T Fiber:

|

|

|

Through the micro-grooves on the fiber surface, it exhausts the moisture vapor and sweat from the skin surface by wicking, expansion and conveyance, and keeps the skin dry and cool, and adds spinning raw material with UV-CUT into the fiber center to prevent the skin from ultraviolet, it is a kind of multifunctional complex product which are suitable for the leisurewear market.

|

|

Polyester Triangle Mid-Hollow Fiber With Far Infrared Ray:

|

| |

ts fiber surface with three porous-holes is just like the lotus root slice, and adds the far infrared ray substance into the fiber center. It is provided with its lightness and warm-keeping.

|

|

|

|